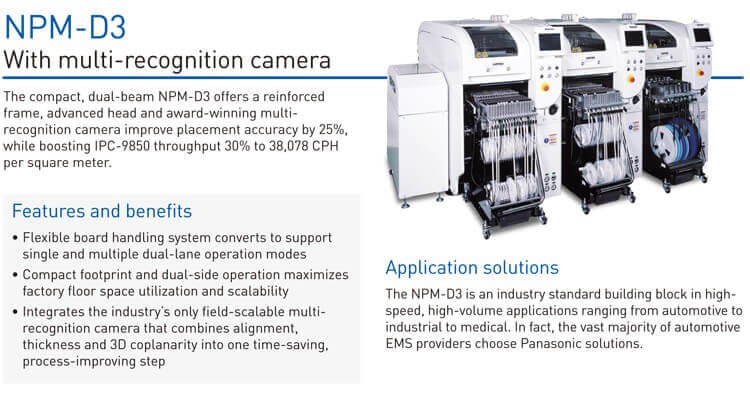

Panasonic SMT Chip Mounter NPM-D3

Panasonic NPM-D3A Modular Pick And Place Machine

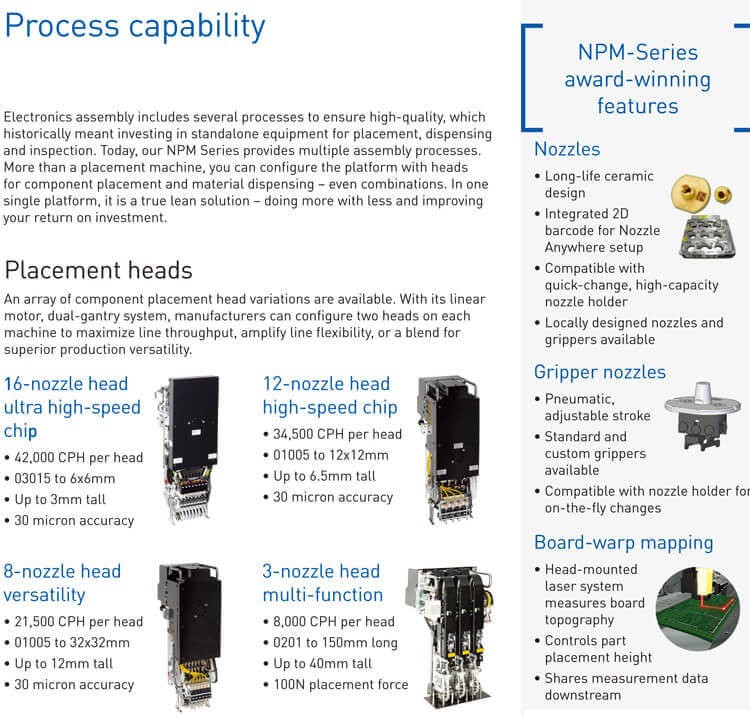

Adoption of the light-weight 16-nozzle head V3

Improving Placement tact time by simultaneously driving X-/Y-axes and selecting optimal pathways during component recognition operation.

Advancement of head drive unit motion control

Improving placement tact time by further advancing motion control and thereby reducing X-/Z-axis travel time.

Use of new pickup operation algorithm

Improving effective productivity by enhancing pickup algorithm for microchips.

Keywords:

Pick and Place Machine,Panasonic Pick and Place,Panasonic Pick and Place Machine,Panasonic Smt Mounter,SMT Pick and Place Machine,Pick Place Machine,Panasonic Chip Mounter,Panasonic Shooter,Panasonic Smt Placement,Panasonic Chip Placement,High Speed Chip Shooter,Panasonic Chip Shooter,SMTChip Shooter,Panasonic SMT,Panasonic NPM,Panasonic NPM-D3,Panasonic NPM-DX,Panasonic NPM-W2,Panasonic NPM-W2S,Panasonic NPM-WX,Panasonic NPM-WXS,Panasonic NPM-TT2,Panasonic NPM-VF,Panasonic NPM-X Series,Panasonic CM602,Panasonic CM402,Panasonic AM100,Panasonic CM401,Panasonic DT401,Panasonic CM101,Panasonic CM301.

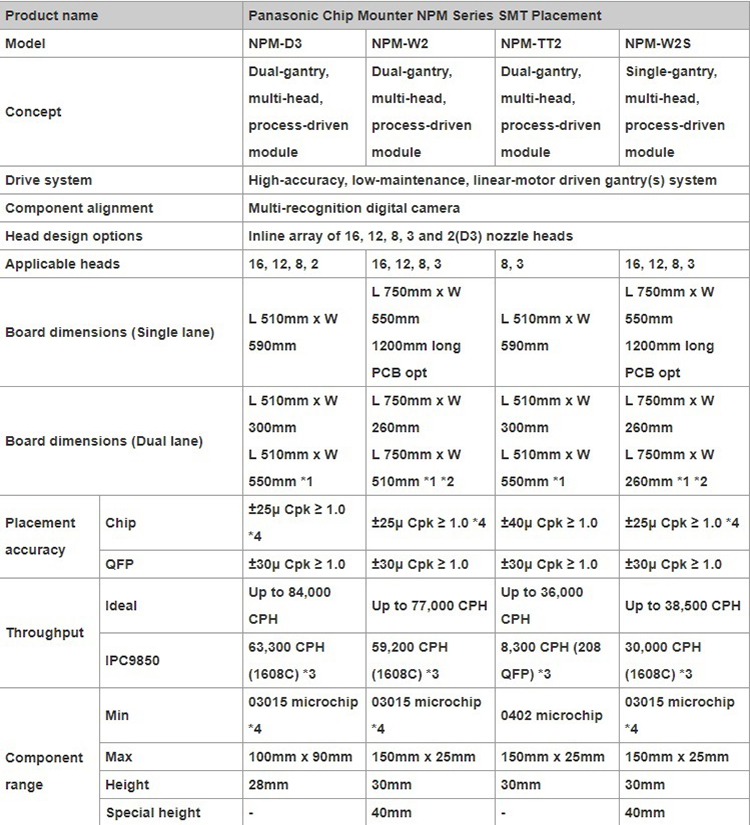

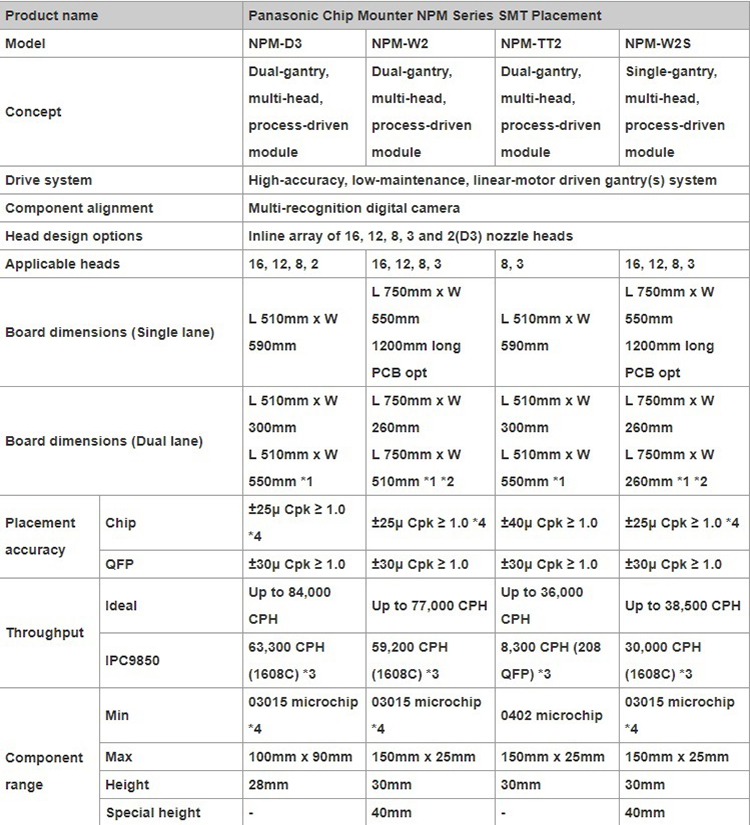

Specification

|

Model ID

|

NPM-D3

|

|

Rear head

Front head

|

Lightweight

16-nozzle head

|

12-nozzle head

|

8-nozzle head

|

2-nozzle head

|

Dispensing head

|

No head

|

|

Lightweight 16-nozzle head

|

NM-EJM6D

|

NM-EJM6D-MD

|

NM-EJM6D

|

|

12-nozzle head

|

|

8-nozzle head

|

|

2-nozzle head

|

|

Dispensing head

|

NM-EJM6D-MD

|

|

NM-EJM6D-D

|

|

Inspection head

|

NM-EJM6D-MA

|

|

NM-EJM6D-A

|

|

No head

|

NM-EJM6D

|

NM-EJM6D-D

|

|

|

PCB

dimensions*1

(mm)

|

Dual-lane mode

|

L 50 x W 50 ~ L 510 x W 300

|

|

Single-lane

mode

|

L 50 x W 50 ~ L 510 x W 590

|

|

PCB

exchange

time

|

Dual-lane

mode

|

0 s* *No 0s when cycle time is 3.6 s or less

|

|

Single-lane

mode

|

3.6 s* *When selecting short conveyors

|

|

Electric source

|

3-phase AC 200, 220, 380, 400, 420, 480 V 2.7 kVA

|

|

Pneumatic source *2

|

0.5 MPa, 100 L /min (A.N.R.)

|

|

Dimensions *2 (mm)

|

W 832 x D 2 652 *3 x H 1 444 *4

|

|

Mass

|

1 680 kg (Only for main body:This differs depending on the option configuration.)

|

|

Placement head

|

Lightweight 16-nozzle head

(Per head)

|

12-nozzle head

(Per head)

|

8-nozzle head

(Per head)

|

2-nozzle head

(Per head)

|

|

High production mode [ON]

|

High production mode [OFF]

|

|

Max. speed

|

42 000 cph

(0.086 s/ chip)

|

38 000 cph

(0.095 s/ chip)

|

34 500 cph

(0.104 s/ chip)

|

21 500 cph

(0.167 s/ chip)

|

5 500 cph (0.655 s/ chip)

4 250 cph (0.847 s/ QFP)

|

|

Placement accuracy

(Cpk□1)

|

± 40 µm/chip

|

±30 μm / chip

(±25 μm / chip*5)

|

±30 μm / chip

|

± 30 µm/chip

± 30 µm/QFP

□ 12mm to

□ 32mm

± 50

□ 12mm Underµm/QFP

|

± 30 µm/QFP

|

|

Component dimensions

(mm)

|

0402 chip*6 to L 6 x W 6 x T 3

|

03015*6*7/0402 chip*6 to L 6 x W 6 x T 3

|

0402 chip*6 to L 12 x W 12 x T 6.5

|

0402 chip*6 to L 32 x W 32 x T 12

|

0603 chip to L 100 x W 90 x T 28

|

|

Component

supply

|

Taping

|

Tape : 4 / 8 / 12 / 16 / 24 / 32 / 44 / 56 mm

|

|

|

Taping

|

Max. 68 (4, 8 mm tape, Small reel)

|

|

Stick

|

|

Max.16 (Single stick feeder)

|

|

Tray

|

|

Max.20 (per tray feeder)

|

|

Dispensing head

|

Dot dispensing

|

Draw dispensing

|

|

Dispensing speed

|

0.16 s/dot (Condition : XY=10 mm, Z=less than 4 mm movement, No θ rotation)

|

4.25 s/component (Condition: 30 mm x 30 mm corner dispensing)*8

|

|

Adhesive position accuracy

(Cpk□1)

|

± 75 μ m /dot

|

± 100 μ m /component

|

|

Applicable components

|

1608 chip to SOP,PLCC,QFP, Connector, BGA, CSP

|

SOP,PLCC,QFP, Connector, BGA, CSP

|

|

Inspection head

|

2D inspection head (A)

|

2D inspection head (B)

|

|

Resolution

|

18 µm

|

9 µm

|

|

View size (mm)

|

44.4 x 37.2

|

21.1 x 17.6

|

|

Inspectionb processing

time

|

Solder

Inspection*9

|

0.35s/ View size

|

|

Component

Inspection*9

|

0.5s/ View size

|

|

Inspection

object

|

Solder

Inspection *9

|

Chip component : 100 μm x 150 μm or more (0603 mm or more)

Package component : φ150 μm or more

|

Chip component : 80 μm x 120 μm or more (0402 mm or more)

Package component : φ120 μm or more

|

|

Component

Inspection *9

|

Square chip (0603 mm or more), SOP, QFP (a pitch of 0.4 mm or more), CSP, BGA, Aluminum electrolysis capacitor, Volume, Trimmer, Coil, Connector*10

|

Square chip (0402 mm or more), SOP, QFP (a pitch of 0.3 mm or more), CSP, BGA,Aluminum electrolysis capacitor, Volume, Trimmer, Coil, Connector*10

|

|

Inspection

items

|

Solder

Inspection *9

|

Oozing, blur, misalignment, abnormal shape, bridging

|

|

Component

Inspection *9

|

Missing, shift, flipping, polarity, foreign object inspection *11

|

|

Inspection position accuracy *12

( Cpk□1)

|

± 20 μm

|

± 10 μm

|

|

No. of

inspection

|

Solder

Inspection *9

|

|

|

|

Component

Inspection *9

|

|

|

|

*1 :

|

Due to a difference in PCB transfer reference, a direct connection with NPM (NM-EJM9B) / NPM-W (NM-EJM2D) /NPM-W2 (NM-EJM7D) dual lane specs cannot be established.

|

|

*2 :

|

Only for main body

|

|

*3 :

|

Dimension D including tray feeder : 2 683 mm

Dimension D including feeder cart : 2 728 mm

|

|

*4 :

|

Excluding the monitor, signal tower and ceiling fan cover.

|

|

*5 :

|

±25 μm placement support option.(Under conditions specified by Panasonic)

|

|

*6 :

|

The 03015/0402 mm chip requires a specific nozzle/feeder.

|

|

*7 :

|

Support for 03015 mm chip placement is optional.(Under conditions specified by Panasonic:Placement accuracy ±30 μm / chip )

|

|

*8 :

|

A PCB height measurement time of 0.5s is included.

|

|

*9 :

|

One head cannot handle solder inspection and component inspection at the same time.

|

|

*10 :

|

Please refer to the specification booklet for details.

|

|

*11 :

|

Foreign object is available to chip components. (Excluding 03015 mm chip)

|

|

*12 :

|

This is the solder inspection position accuracy measured by our reference using our glass PCB for plane calibration. It may be affected by sudden change of ambient temperature.

|

*Placement tact time, inspection time and accuracy values may differ slightly depending on conditions.

*Please refer to the specification booklet for details.

Shenzhen Yufuxin Technology Co., Ltd.

Shenzhen Yufuxin Technology Co., Ltd.