Panasonic NPM DX Pick and Place Machine

The NPM-DX Pick and Place Machine provides a greater line throughput, better quality and lower production cost featuring an autonomous line control, which guaranties a stable operation based on automatic functionality. This functionality in combination with the machine set up offers a labor-saving production with improved utilization.

92 400 cph and feeding with up to 136 reels

Model ID

PCB dimensions (mm)

*When the long spec. conveyor is selected

Single-lane mode

L 50 × W 50 ~ L 510 × W 590

Dual-lane mode

L 50 × W 50 ~ L 510 × W 300

PCB exchange time

*When the short spec. conveyor is selected

2.1 s ( L 275 mm or less)

Electric source

3-phase AC 200, 220, 380, 400, 420, 480 V 5.0 kVA

Pneumatic source *1

Min.0.5 MPa、200 L /min (A.N.R.)

Dimensions (mm)

W 1 665 *2 × D 2 570 *3 × H 1 444 *4

Mass

3 600 kg (Only for main body:This differs depending on the option configuration.)

Placement head

Lightweight

Lightweight

4-nozzle head

Max. speed

46 200 cph

24 000 cph

8 500 cph (0.424 s/ chip)

Placement accuracy (Cpk≧1)

±25 μm/Square chip

±25 μm/ Square chip

±20 μm/ QFP

Component dimensions (mm)

0201 component *5*6 / 03015 component *5

0402 component *5 ~L 45 x W 45 or L 100 x W 40 x T 12

0603 chip ~ L 120 x W 90 or L 150 x W 25 x T 30

Component

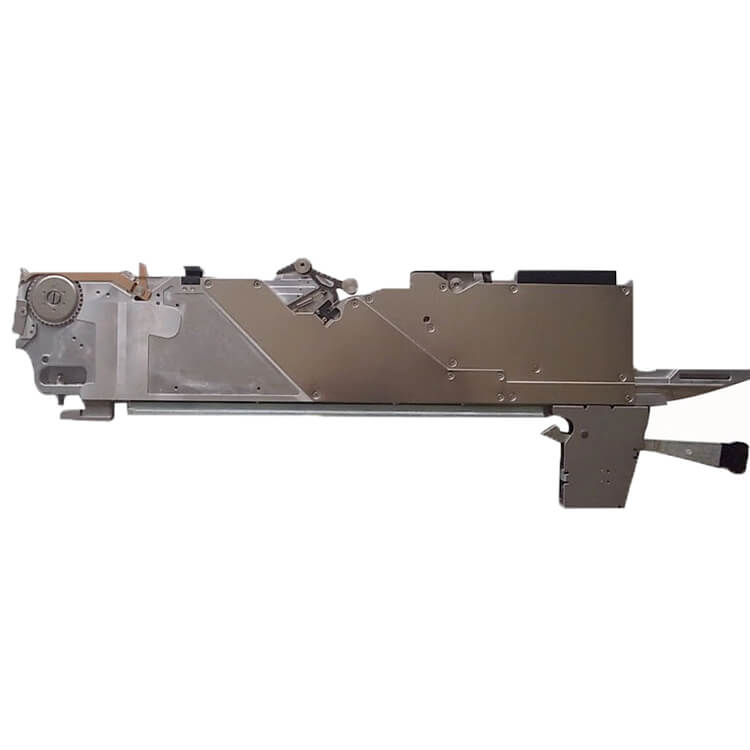

Taping

Tape:4 / 8 / 12 / 16 / 24 / 32 / 44 / 56 mm

Tape:4 ~56 /72 / 88 / 104 mm

4, 8 mm tape:Max. 136

Stick

Max. 32 (Single stick feeder)

In combination with the Panasonic software environment and embedded into an Industry 4.0 philosophy, the user can expect a modern shop floor management system including various remote operation options, feeder setup navigation, component supply navigation etc.

In total, the NPM-DX reduces downtimes and increase the line throughput.

With 92 400 cph and a feeder capacity for up to 136 reels, the NPM-DX is the ideal solution to meet the expectation of an evolving electronics assembly industry.

The NPM-DX can process PCB sizes of up to 510 x 590 mm and place large connectors (up to 150 x 25mm) and other components (up to 120 x 90mm).

This and other features make the NPM-DX the best solution for high volume-mix manufacturing.

Ready for line automatization

Available APC system

Automatic recovery options

Remote operation option

Lowest total cost of ownership (TCO) with maintenance services

Advanced feeder setup and component supply navigation

Integrated floor management

4.8 s ( L 275 mm or over to L 460 mm or less) *May differ depending on PCB specifications.

*1 : Only for main body

16-nozzle head V2

(Per head)

8-nozzle head

(Per head)

(Per head)

(0.078 s/ chip)

(0.150 s/ chip)

8 000 cph (0.450 s/ QFP)

±40 μm/QFP □12 mm Under

±25 μm/QFP □12 mm to □32 mm

0402 component *5 to L 6 x W 6 x T 3

supply

*2: 2 265 mm in width if extension conveyors (300 mm) are placed on both sides.

*3: Dimension D including feeder cart

*4: Excluding the monitor, signal tower and ceiling fan cover.

*5: 0201/03015/0402 component requires a specific nozzle/tape feeder.

*6: 0201 component placement is optional. (Under conditions specified by Panasonic)

* Placement tact time and accuracy values may differ slightly depending on conditions.

* Please refer to the specification booklet for details.

Shenzhen Yufuxin Technology Co., Ltd.

Shenzhen Yufuxin Technology Co., Ltd.